Integrated Project Delivery: Perspectives and Lessons Learned

Increasing Efficiency to Achieve the Highest Value

October 10, 2017It has been widely recognized and documented that the design and construction industry has not kept pace with the productivity and efficiency gains other industries have achieved in the past 50 years. While these measurements of productivity don’t take into account the fact that the industry is producing better buildings that are higher performing than in the past, it does point out a design and construction process that is in desperate need of transformation.

Problem Definition

Most projects are delivered in much the same way they were 20 years ago and budget overruns and schedule busts are common. There is an inordinate amount of waste in the process due to rework, redundancy and lack of coordination. Even when new technologies are introduced, such as BIM (Building Information Modeling), design teams and contractors typically don’t share the same system. It is not uncommon for a design team to produce a detailed model of the building only to have the contractor redraw the entire model so that it is compatible with their shop drawing and fabrication systems and those of the trades that work with them.

Much of this waste is caused by the adversarial relationship that developed over the years between contractors and design teams because of litigation around liability. Both sides became more focused on pointing fingers to protect themselves than in solving problems together. This lack of collaboration is not only counterproductive and wasteful, it suppresses the kind of innovation that is generated when problems are analyzed from multiple perspectives.

Another aspect of the process that reduces collaboration and reinforces the already adversarial relationships is the short-term viewpoint that teams take. In most cases once the project is turned over to the client the design and construction team are done and move on to the next project. The teams do not stay involved post-occupancy to make sure the project is operating as designed and that the client and users are happy with the building. This short-term thinking tends to create a mentality similar to short-timers syndrome; the team is just trying to finish the project and is not invested in its long-term success. They can walk away.

We believe there is a better way to work. As the result of our experience with new delivery models that are based on a culture of collaboration and trust, which involves deep engagement with the owner and early involvement with the contractor and their trade partners, we have been able to deliver higher value projects for our clients while staying within their budget and schedule. In many cases we have been able to deliver innovative projects faster and for less money than the client originally thought.

For the purposes of this white paper we are going to use the term Integrated Project Delivery (IPD) for this delivery model. This does not refer to the type of contracting method used, but describes the actual process and structure for how the project is delivered. We have worked on projects with integrated teams that used a CM/GC (Construction Manager/General Contractor) contract. Other IPD projects have been contracted as design-build. Still others have used a form of three party agreement. Often there has been a secondary contract document, such as a Memorandum of Understanding, that describes the relationship between the parties involved and how they are expected to behave. On all of these projects, we have found that the contract is not as important as the attitude that everyone brings to the project.

One essential element that is a feature of all successful IPD projects is they are built around a core team that includes the client, contractor and architect as equals, dedicated to making decisions together based on what is best for the project. Working collaboratively toward a common goal, the core team’s primary responsibility is to create a culture of transparency, trust and mutual respect that brings out the best in everyone working on the project. This can be accomplished in a variety of ways, but we believe developing a project charter and Guiding Principles, which together establish both the project’s goals and the rules for team behavior, can provide a blueprint for success. These documents are not contractual, but they are the glue that binds the team together with a common purpose.

Achieving this is easier said than done. It requires commitment and a clear understanding that the team cannot work in the traditional way. Building a collaborative culture takes time and planning. Not everyone is a good fit. Tools for collaboration such as pull planning, continuous cost estimating using Target Value Design, and design that includes the trade partners who build the project in the field, provide a new framework for how teams work together. Using IPD, we believe teams can deliver on a clients’ most ambitious aspirations and create high-value projects that would otherwise be impossible within limited project budgets. This white paper was created to share the lessons we have learned on four IPD projects, including how to set up the project for success, the management processes and the tools available to support the process.

First, we will provide a quick review of how we got to this point, so that we can better understand the litigious, non-collaborative situation we find ourselves in and how IPD can address the issues that arise with traditional delivery models.

Historic Perspective

Historically there have been 2 major paradigms for how projects were delivered in the design and construction industry: The first was the Master Builder and the second was what we are calling the Industrial Assembly Line model. These two paradigms, or ways of working, shaped our built environment from the antiquities to the late 20th century. Now, in the 21st century, we are amid a paradigm shift to a third model that is revolutionizing the industry and which embodies the future of our profession. To understand that paradigm shift it is helpful to understand the first two paradigms.

The Master Builder

Once upon a time all buildings were built by a master builder. There was no distinction between architecture, engineering and construction. One person was responsible for all three and the project was done by a single team, which was involved from design through project completion. One person determined the form, the materials and the final construction methods of a project. One person also took responsibility for all the challenges that arose during the project. This was the predominant model or paradigm throughout most of history; all the great monuments of historic times, from the Parthenon to the Pantheon, were designed and built by a master builder. This intuitively makes sense as construction techniques and engineering challenges were part of the design thinking. Design decisions could be made during construction to ensure the final building embodied the master builder’s vision. There were also no separate systems in these buildings – the structure was embedded in the building exterior or envelope and of course there were no mechanical or electrical systems before the advent of electricity.

The Master Builder paradigm began to break down during the late Renaissance, when buildings became more complicated. Trades were established to design and build various elements of the project and laws began to differentiate between the art of architecture, the science of engineering, and the craft of building. The architect was still in charge, but was no longer responsible for every aspect of the project.

The Master Builder paradigm finally shifted completely with the beginning of the industrial revolution and the advent of Henry Ford’s assembly line.

The Assembly Line Model

In Ford’s assembly line, each worker had one job: to put his or her part on the car chassis as it rolled past. This linear process in which the assembly moved on a conveyor belt at a predictable rate kept workers focused and efficient. This significantly cut production time and the cost of each car.Ford’s innovation revolutionized production and the assembly line is still the predominant mode of industrial manufacturing today. This century-old innovation by a car manufacturer in Michigan changed the way we live and work forever.

Up until recently, buildings were designed and constructed in a similar assembly line manner. The client, or future building owner, hired the architect, gave him or her the basic program – the number of rooms and their sizes and functions – and the architect turned the program into a basic design. The architect then handed the plans to the engineers, who added structural, mechanical, electrical and other building elements to the drawings. Once the drawing set was completed, it was turned over to the contractor, who provided a cost for the building and then built it, with some overview from the architect.

It sounds simple and efficient. The problem is, the process was rarely as linear as an assembly line. There was usually a significant amount of backtracking and rework involved with every hand-off. It might be the engineers discovering that the systems they wanted to put in the building didn’t fit easily and the architects had to redesign the project to make room for them. Or the price the contractor provided was significantly above the budget the owner had established, which meant going back to the beginning and cutting program and then redesigning the building to accommodate the new program. There are dozens and dozens of variations on this theme.

Even worse, because there is significant money spent on building projects, there is significant risk to the owner if the project takes longer than anticipated or if there are problems with the building that someone must pay to fix. Who is responsible? How do you place blame and determine who pays for the problem?

Laws and legal contracts were developed to protect each party in the process, which pitted the architect against the contractor in a dance to avoid taking responsibility for someone else’s error.

By the end of the 20th century the process in many cases was adversarial, with the architect and engineers leery of the contractor’s appreciation of design and the construction team convinced that the design team didn’t really care about cost, schedule or constructability. Countless clients, were stuck in the middle, began to think there had to be a better way to design and build a building.

Experience in IPD

SRG Partnership is currently working on four significant IPD projects. Each project is unique, and each has a different reason for using IPD, but all share common traits and lessons learned. These common traits and lessons learned form the basis for this white paper.

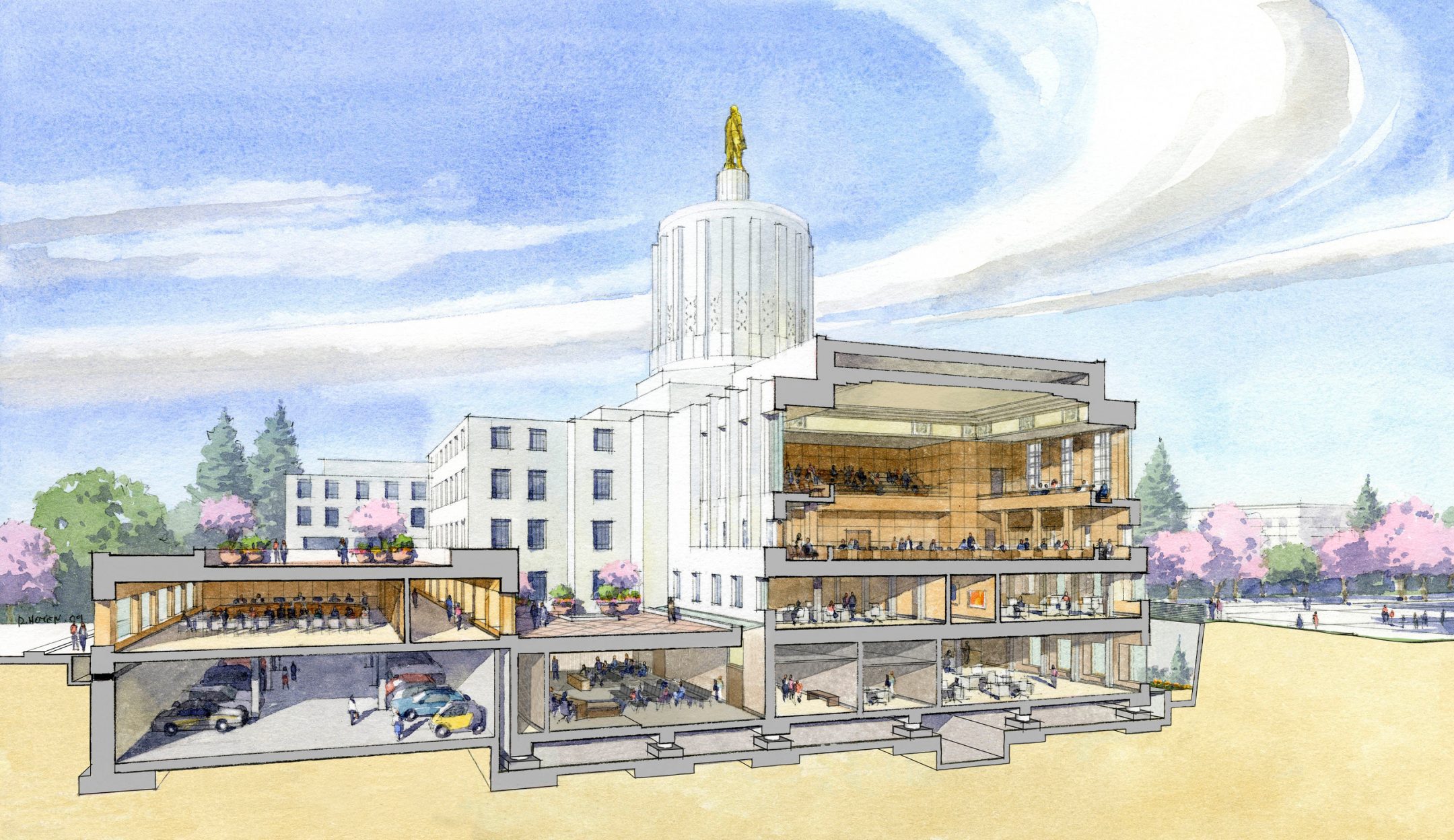

Oregon State Capitol Building

Contracting method: CM/GC

Institutional goals: Deliver the project faster and for less cost than traditional methods

Oregon Health & Science University, Knight Cancer Research Building

Contracting method: CM/GC with a Memorandum of Understanding and behavior agreement that informally binds the A/O/CM together with a risk-reward incentive

Institutional goals: Collaboration that drives innovation to create a state of the art research environment, reduces risk and creates value for the owner

Multnomah County Central Courthouse

Contracting method: CM/GC with GMP after complete bid out. Owner placed $800,000 available for design and construction fee incentive

Institutional goals: Reduce risk. Manage contingencies. Provide certainty for County board.

Process for Forming an Efficient IPD Team

Establish the Desired Culture

The primary goal of IPD is to turn the design team, the construction team and the client into a single high-performance enterprise focused on project success, rather than each entity’s individual success or liability. One of the biggest challenges to achieving this is trying to form one consistent culture out of these three different culture types, all of which tend to be driven by a different set of goals and behaviors.

Design

At its heart, design is an exploration of the unknown. It is a non-linear, iterative process that seeks to find the optimum creative solution to meet the owner’s needs while staying within the budget. This requires the design team to be comfortable with uncertainty for an extended period as it explores different options for the project.

Construction

Construction, on the other hand, is the exact opposite. It seeks to be as linear as possible and to eliminate any unknowns on the project. Determining how contractors can contribute during the design process and how architects can communicate better with the people constructing the building is an important part of making both the process and the project more successful.

Client

The client may have the biggest cultural shift to make – they must understand both design and construction well enough to play an active role in the process. The tradeoff is that the client becomes much more embedded in the process, gaining a much deeper understanding of whether or not the project is responding to his or her needs. By providing real-time feedback the client can guide the design and construction team as it seeks to provide them value for their investment.

There are a number of strategies for building a coherent, high performing culture. The most important among these is transparency. Being willing to share information broadly across the team, including the rationale for decisions and information about the economic performance of the team, is a key element in building trust.

There are also tools that can be used for building a collaborative culture. On KCRB, for example, the entire team did a StrengthsFinder workshop, that identified each person’s top five strengths. This exercise helped team members get to know each other better, provided insight into how to work together by playing to everyone’s strengths, and built trust as each team member became a person and not just a functional role player. The strengths were displayed on each team member’s desk, opening up opportunities for conversation with no hierarchy between team mates.

Another way teams built trust was through activities outside the pressures of the project. Team barbecues, celebrations of success and other social opportunities brought the team together and broke down the traditional client, contractor and designer roles. On KCRB, contractors, engineers, designers and members of the client group put together a Hood to Coast relay team, running a collective 200 miles in five-mile legs. Successfully completing this rigorous race demonstrated that team-mates could work toward a common goal and built trust that everyone would play their part. It also created a point of pride across the entire project.

Develop the Project Vision, Mission, and Guiding Principles

Setting up an IPD team is very similar to starting a new business. Clarity and consensus across the team about the mission, vision, and values of the project is critical to success. Developing these collaboratively, with all of the key players involved, not only sets the project on the right path, it is an important team building opportunity.

Guiding Principles

The Guiding Principles are established by the Project Leadership and articulate the project’s goals, including how user groups will occupy the building. These principles establish a framework that can be used for decision making throughout the project, empowering team members to make many decisions without input from the core team or the client’s senior leadership.

For the Guiding Principles to be effective, everyone on the team must fully understand and support them. On the KCRB, a first draft of the Principles was established by leadership at the Knight Cancer Institute. Each Guiding Principle has a robust definition which clarifies its true intent. These Principles were reviewed and discussed by the core team, the client user groups, the Project Advisory Group and the rest of the project team. While this process required a significant time investment early in the project, it paid off in commitment to the project’s goals, enhanced collaboration by the entire team and streamlined decision making during the rest of the project.

The following Guiding Principles from KCRB illustrate how the project’s goals were articulated:

Intellectual & Social Hub. KCRB is the heart of the Knight Cancer Institute. Services and amenities for all of the Knight Cancer Institute draw all to meet and collaborate there. promoting a sense of community. At the more public ground-floor level, a state-of-the-art conference center expands the reach of the Knight Cancer Institute, inviting in visitors, partners and all OHSU departments. Conference spaces, eating areas and amenities on upper floors encourage interaction among all building occupants.

Vertical Campus. The building functions as a vertical campus, with visual and physical connections between floors to promote interaction and collaboration between researchers. The building has an engaging community feel much like a high-tech company working toward a common goal in a creative team environment.

Functional & Flexible. Lab space is flexible, reflecting the fast-changing scientific landscape, and supporting the non-territorial culture and the conduct of team science.

The Project Charter

The Project Charter pulls together all of the key documents and decisions that collectively form the basis for the team culture, which guides the team’s behavior on the project. The charter includes:

- Project mission, vision and values

- Team mission and behavioral guidelines

- Guiding Principles

- Identity of project stakeholders

- Team member roles and responsibilities

- Decision making protocols

- Means and methods of communication

- Big Room hours and meeting schedules

IPD requires a different mindset than traditional delivery methods. The charter session and document should clearly outline how everyone will work together to build a high-performance team and collaborative culture.

Developing a culture based in trust with a large team, which is ever evolving and working in a new shared environment, requires a carefully established onboarding process and team-building environment. Not only is it important to understand different working styles and behaviors, but working hours, meeting schedules, communication styles, meeting formats and shared technology platforms all have to be clearly developed and articulated.

In order to get buy-in on all of these issues at KCRB, teams hosted several host big-room days, a full day of activities that facilitated development and understanding of the culture and the necessary behaviors to achieve the desired outcomes. Some of these were facilitated by invited leadership teams from other projects, and some were culture building exercises developed by the team. Each big room day began with concern about losing productive work time, but they all ended with a greater commitment to the project’s goals and process. Go slow to go fast has its advantages.

Decision Making

One of the key elements of the project charter is to determine how decisions will be made, including the composition and decision-making responsibility of the core team. It is also important to identify how the rest of the design and construction team, as well as key stakeholders for the client, will interface with the core team on decisions. What kinds of decisions can be made at the team level? What decisions need to be made by the core team? What decisions need to be brought to a higher level in the client’s organization, for example a Steering Committee, Board of Directors or project oversight committee? Ideally the Core team is empowered to make most decisions so that the process doesn’t get bogged down waiting for executives from the client group to weigh in.

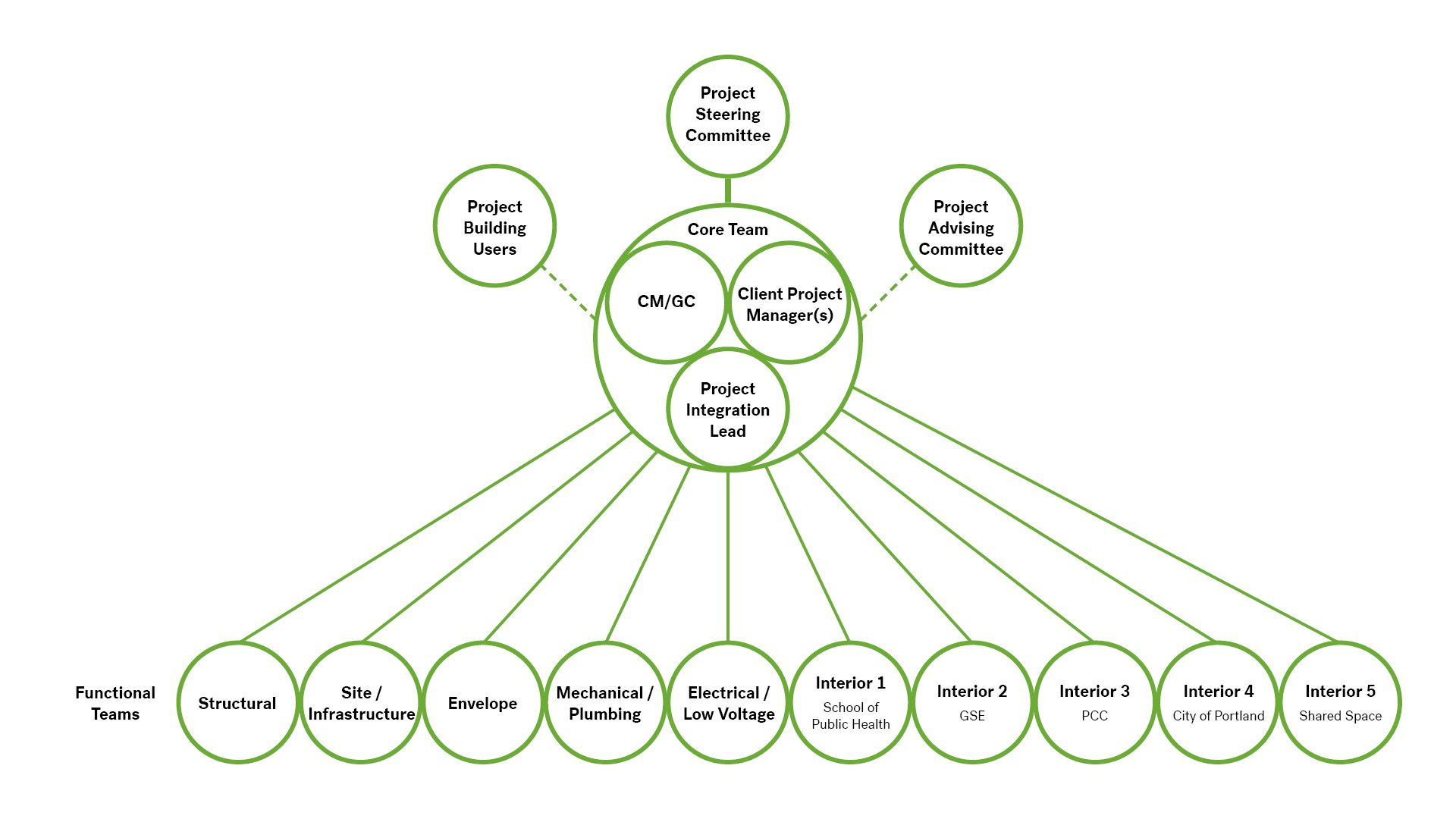

Leadership Structure at the Knight Cancer Research Building

The following chart shows the leadership and decision making structure for the Knight Cancer Research Building. In addition to the Core Team (at the center of the chart), some decisions required involvement or approval from the Project Steering Committee, made up of senior leadership from the client group (Oregon Health & Science University and The Knight Cancer Institute). User Groups from the client and a Project advising Group, both made up of key stakeholders on the project, provided input to the Core Team and reviewed project progress.

SRG Project Manager Laurie Canup was the core team member representing the design and engineering team. In this case she was given the title of “Project Integration Lead” because a key part of her job description was to make sure the various members of the project team were working together and the process was integrated, with nothing taking place in isolation. Laurie worked directly with the core team members from the client and contracting groups to lead the project, facilitate decisions and to coordinate participation among all of the client groups. She also had responsibility for communicating with her team members to facilitate coordination of the Functional Teams on the project, which are listed below the core team on the org chart.

The Functional Teams, made up of representatives from across the design and construction team, were responsible for the key elements of the project. For example, the Structural Functional Team included an architect, a structural engineer, the contractor who would be responsible for structure, and the contractor’s structural trade partner. They worked together to design the building structure and to make sure it was buildable within the Target Value for the building’s structure (more on this in Target Value Design).

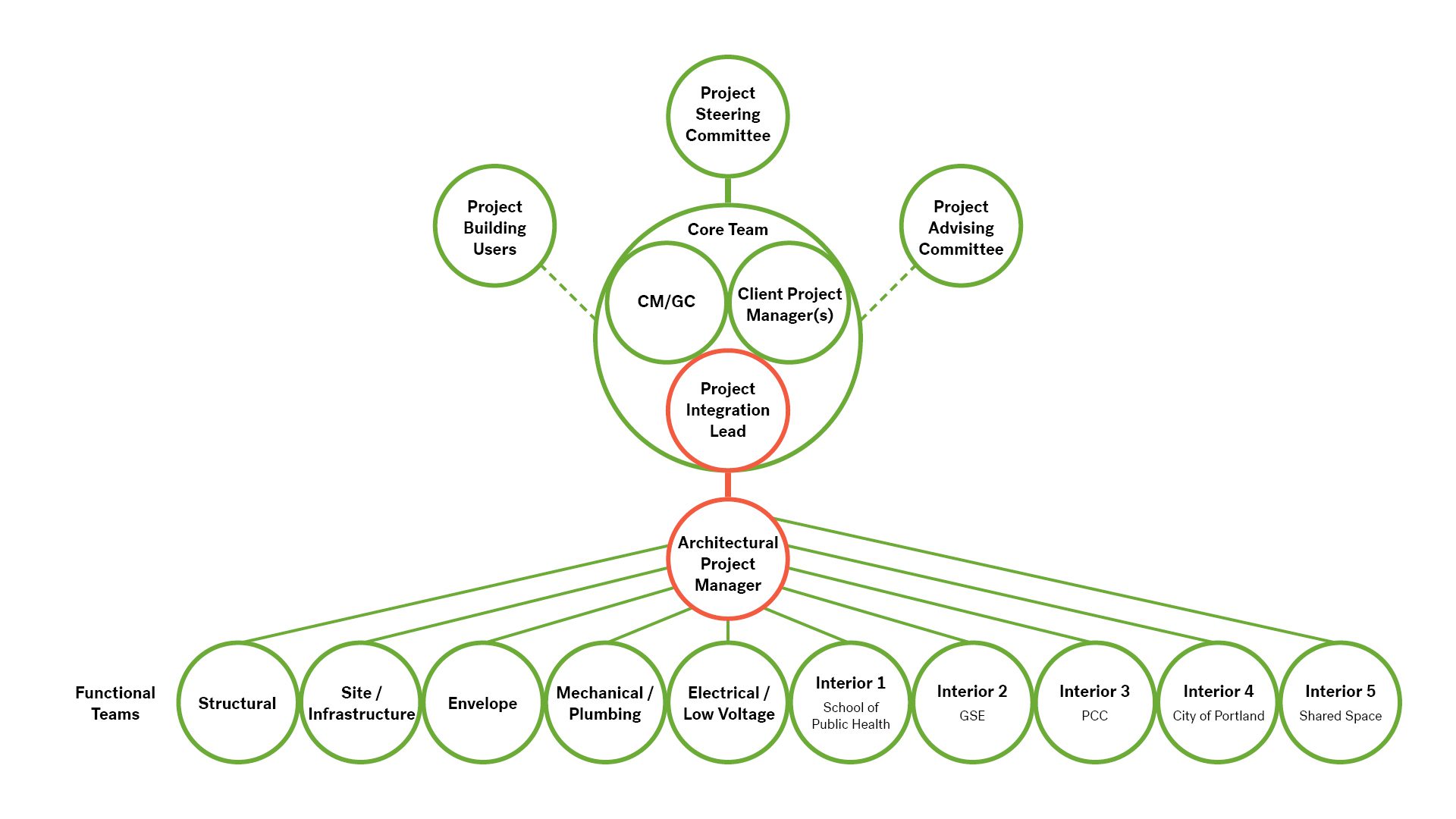

Leadership Structure at 4th and Montgomery

The chart below is a modified version of this organizational structure that is being used on the Fourth and Montgomery Building (FMB), a joint venture between Portland State University, Oregon Health & Science University, Portland Community College and the City of Portland.

While the structure on the Knight Cancer Research Building was successful in many ways, it required an overwhelming time commitment from SRG’s Project Integration Lead. As the project unfolded she realized that facilitating decisions with the client group and coordinating the work of the Functional Teams was actually two full-time jobs and she recruited additional help from the project architects to assist her. For Fourth and Montgomery an Architectural Project Manager was added at the outset to coordinate the Functional Teams, with the goal of focusing on potential synergies and efficiencies between each element of the project. This freed up the Project Integration Lead to focus on input and decision making with the client Group, which with four clients included an even greater number of stakeholders than KCRB. A key to success for this structure is consistent communication and coordination between the Architectural Project Manager and the Project Integration Lead.

Bring the Right People to the Table

We believe it is important to bring the right people to the table, who have the relevant information and background necessary to making a good decision. Importantly, we also find that once the project is established and the teams are collaborating well, there is efficiency in pushing decisions downstream and creating a structure in which the decisions are reported. If there is consensus on a team, in which there are representatives from each entity – the trade, the owner, the consultant, the design team members, and the CM/GC – and the decisions is in alignment with the guiding principles, then we’ve found those decisions do not need to go up to the core team or the Steering Committee. This facilitates an efficient process and keeps the teams running smoothly. When there is disagreement on the direction, purpose or goals, the decisions get pushed up the chain to a higher level. There are a number of decision making tools available that can support this process. Ultimately, the exact tools and processes the team uses to make decisions should be tailored to the culture the team is trying to build.

Co-Location in The Big Room: Develop an Environment Where the Team Can Thrive

On each of SRG’s IPD projects the design, construction and client team has been co-located together in one place, affectionately called the Big Room. These spaces were set up with the infrastructure and technology to support convenient communication and a collaborative working environment, including a variety of large and small meeting spaces. On KCRB, several of the Functional Teams had a dedicated small conference room where they could leave work in progress on the walls, providing day to day continuity and enabling everyone in the Big Room to see the work in progress. Other key spaces in the Big Room include a pull planning wall, design workshop area, team recognition wall and a kitchen and dining area.

Determine Who is Doing What When

Co-location does not mean everyone on the team is in the Big Room every day, from day one. The benefits of co-location are clear – collaboration and multiple perspectives can spur innovation; easier and faster sharing of knowledge facilitates better decisions and builds trust. But it is neither efficient nor effective to have everyone there all the time. The key is to have the right people in the room at the right time. Determining how to make efficient and effective use of the resources at the project’s disposal is a key part of the project charter and one of the Core Team’s most important responsibilities. This means keeping the Big Room small when necessary, especially earlier in the programming and design process, by bringing together appropriate team members at decision points, when their input is most valuable. As the team moves into development of the BIM (Building Information Model) more team members will be co-located to work through the various details and issues on the project together.

Process for Managing an Efficient IPD Team

Go Slow to Go Fast

“Go slow to go fast” means that if the project team works collaboratively and takes the time necessary to collectively resolve as many of the design and technical issues as possible during design and generation of the BIM, then the construction process can go faster and risk can be minimized. Part of the “Go Slow” period is also used to build trust and a collaborative relationship between team members. When done well the result is a project that meets or potentially shortens the overall schedule, lowers overall project costs (making changes in the BIM is much cheaper than making them during construction) and creates a better asset for the client.

Maintain the Benefit of Hiring a Design Firm

In addition to the project team, SRG regularly brings together other key members of the firm for design workshops, brainstorming sessions and problem solving. Clients benefit when the team can leverage the entire design firm’s experience and resources on a project, regardless of location. This interaction also keeps the design team’s co-located staff engaged with the home office culture and helps maintain their integration in the firm, which is important so they don’t feel isolated or disconnected during co-location.

Collaborative Design Leadership

Modern leadership for a collective design world means re-thinking design leadership approaches for collaborative work. Effective collaboration, steeped in trust, requires that top-down cultures are re-structured to encourage innovation, which can come from anyone on the team. This means moving from one central design lead with “the big idea” to a project vision championed collectively by the team. This shift in design philosophy from “Big D” designers to “Big C” collaborators requires an adjustment in mindset and how teams work, including changes in who is doing the work. Egos must be checked at the door so that design input and responsibilities can be distributed more deeply across the team, framed and guided by the project vision.

Eliminate Redundancy – Draw it Once

Having the design, engineering and construction team work together on one shared Revit model can eliminate the redundancy that often happens on traditional projects, where the design team draws something and then the construction team redraws it on their own technology platform. One of the challenges is to get sub-contractors to also use the same platform. Many of these businesses are smaller and haven’t yet adopted Revit as their technology tool. This is changing quickly but it is a consideration when selecting subs on the project.

Trust and Verify, Don’t Search for Mistakes

This may seem like a small thing but this is a major shift in mindset. When the team assumes “best intent,” or that everyone is “innocent until proven guilty,” team members rise to the occasion. Quality Control and Quality Assurance is used to confirm the quality of the work. If errors are discovered, the team can work together to resolve them collaboratively. When everyone really believes they are “all in it together,” energy is spent on collective problem solving rather than placing blame.

Use Collaborative Tools to Extend the “Big Room” Reach

Technology can help team members collaborate even when not in the Big Room:

- BIM from anywhere – Collaboration for Revit

- Collaborative document locations – Bluebeam Studio, Smart Sheet and SharePoint

- Video Conference – GoToMeeting, BlueJeans, Lifesize, Highfive

- Remote desktop tools – GotomyPC, VPN, RDP

- Display tools such as ClickShare and Apple TV

Tools and Techniques

Target Value Design

One of the core concepts in IPD is Target Value Design (TVD), a process in which the project team works collaboratively to create as much value for the client as possible within the set budget. How the client defines value is determined early in the project and articulated in the Owner’s Project Requirements (OPR) and the project’s Guiding Principles. Having a contractor who can provide “order of magnitude” cost information during the early design process enables the design team to focus its exploration on those ideas that add value and are feasible based on the budget. It also enables the team to look for synergies that will address multiple cost challenges with a single design move. This requires a cost estimator who understands the design process and can think conceptually along with the team about different design moves and their cost implications.

As the design progresses the contractor’s trade subs can add additional detail to the cost estimates to more accurately reflect actual costs in the field. Engaging the trade partners early means they are more invested in the project and can think creatively about how to achieve the project’s goals within the budget.

The overall project budget is broken down and allocated to each of the functional teams so that they have a target value, which frames decision making. These target values may be adjusted during the project, but it is a zero-sum game. For example, if the target value for structure, has to be revised upward as more detail is developed on systems to be used, then one or more of the other Functional Team’s Target Value must be revised downward to keep the project on budget. Conversely, if one of the Functional Teams generates design ideas and solutions that reduce the cost for their piece of the project, that additional money becomes available for other Functional Teams. Collaboration between the functional teams and with the Core Team is critical to make sure that the budget is allocated where it will provide the most value to the client and achieve the project’s goals.

Pull Planning

Pull planning is a LEAN process tool for scheduling that has been in use by contractors for years. Working backward from a target completion date with specific milestones, tasks are defined and sequenced so that their completion is aligned and coordinated with the work of other team members. Sticky notes are used to represent tasks that need to be completed, with a different colored sticky used for each Functional Team. Some teams are augmenting this with digital versions that can be shared electronically.Everyone on the team attends a weekly pull planning meeting in the Big Room, where key tasks are discussed and tracked. If a functional team is on schedule they move their sticky to the completed section. If the team is not able to meet their deadline they let everyone on the team know so that those effected can adjust and a new deadline can be set. This is not a time for shaming or blaming, but an opportunity for the collective to work together and develop a strategy for getting back on track. The pull planning wall is a living document that provides transparency and accountability. Notes and action items are kept by the project manager and key players involved.

Pull planning works great during construction, when the process is linear, but when the team tries to apply traditional pull planning to the design process without allowing time for iteration, problems invariably arise. This primarily requires a shift in mindset from the construction team to recognize that while the design needs to be resolved within the overall project schedule, it will not always proceed at a constant pace. Flexibility needs to be built in to the process and a high level of communication is required so that the team can stay on schedule while supporting the design effort as it works toward the optimum solution for the client. This is part of the “Go slow to go fast” ethos mentioned above. Conversely, when the design team can see how their process and schedule ultimately impacts everyone else, it provides a sense of urgency to stay on track.

With contemporary computer modeling tools, much more input is available to shape and inform design than in the past. Climate impacts on the building, models to optimize daylighting and façade design, and energy usage models, to name just three, can take time to run but provide a higher level of certainty about future building performance than in the past. This level of inquiry and investigation takes time and needs to be included in the pull planning schedule to support the best design results and the highest value to the client.

Value Analysis (VA) Log

In the Target Value Model, one way to continuously work toward your target is to constantly Value Add. The rough order of magnitude values for these ideas are put on the logs as they become available and then the CM will cost analyze and track the issue. Once incorporated into the design, it is closed on the log.

Risk Log

Similar to the VA log, the Risk Log tracks all possible risks. Contingencies should always align with the risks. This allows the team to carefully measure the risks over time and ensure careful contingency management.

Choose by Advantages

Choosing by advantages (CBA) is a process where everyone on the team reviews the advantages that a particular decision would provide to the project, then uses the resulting list to choose the most advantageous option. CBA is a transparent, consensus-based process that allows the team to collectively make decisions that align with the project’s values.

The A3

Another tool we have found to be effective is an A3, an 11×17” one-page summary of the issues and criteria needed to make a decision. This summary, along with the team’s recommendation, can provide the core team and owner stakeholders with concise and clear information for decisions.

Last Responsible Moment

This is the most difficult but most exciting possibility for budget management. Keep the project whole for as long as possible and always keep a path back to budget. Make the decision at the last responsible moment. Make the decision early enough that the full value is available, but late enough that if the risks are mitigated and contingency freed, the scope doesn’t have to be cut at all. This enables the team to get more out of the budget.

Conclusion

In the design and construction industry there’s an old axiom that says you can’t have faster, cheaper and better, you must choose two of the three. We believe the real power of IPD is its potential to achieve all three. Each project will differ in the degree these are achieved based on what’s most important to the client. If building quality is the key driver, then achieving the highest value solution within the budget and schedule may be the goal.

We have found that innovation, which challenges the status quo, is the biggest benefit of IPD. It can be innovation that reduces waste and cost, or innovation that eliminates inefficiencies and redundancy to shorten the overall schedule, or innovation that improves building performance and the project’s ability to achieve the client’s mission and vision. All are possible when the team is working at its full potential. Unleashing that potential is the ultimate goal of Integrated Project Delivery.