Reducing our Carbon Footprint with Mass Plywood Panels

Laurie Canup, David Webb

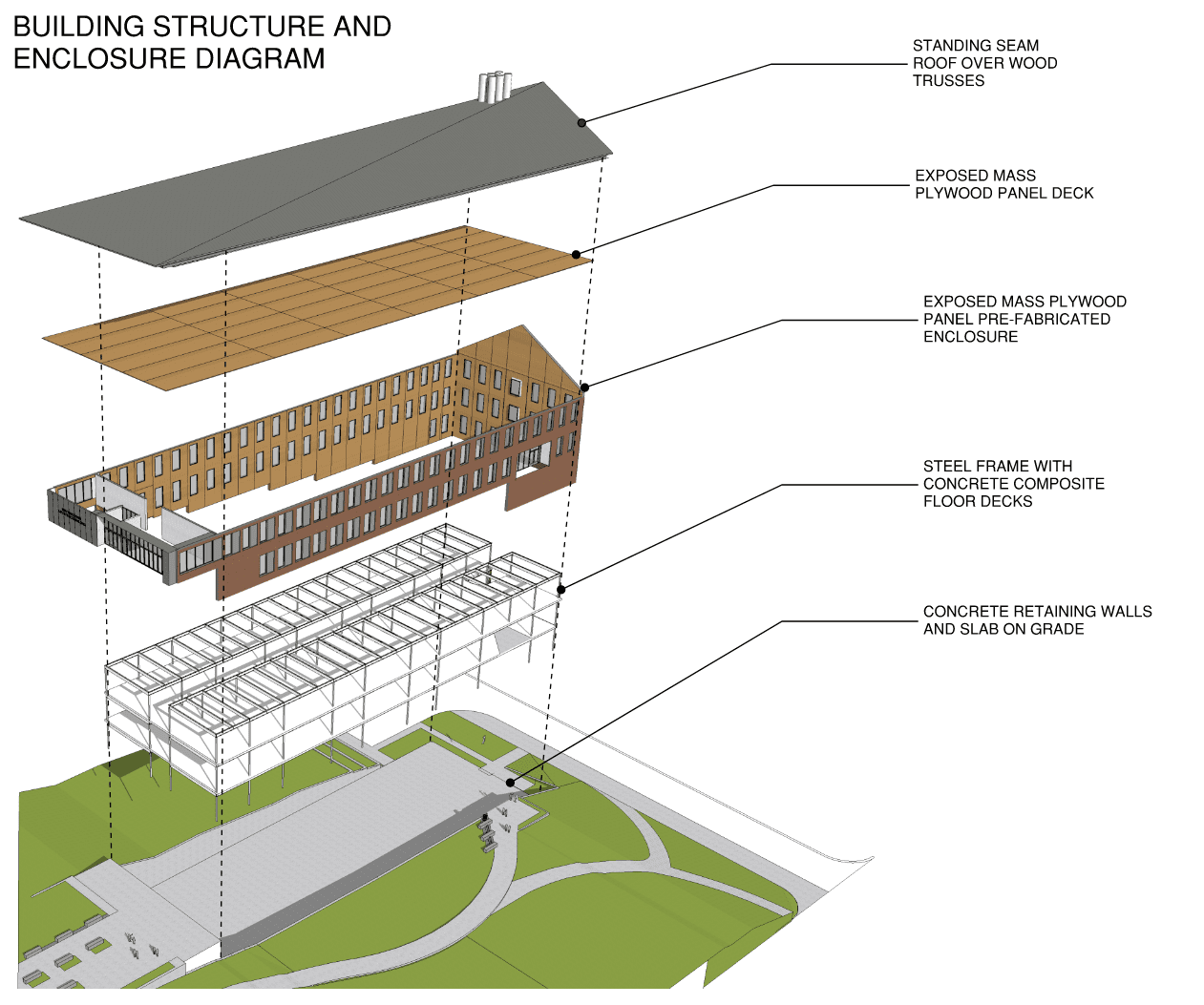

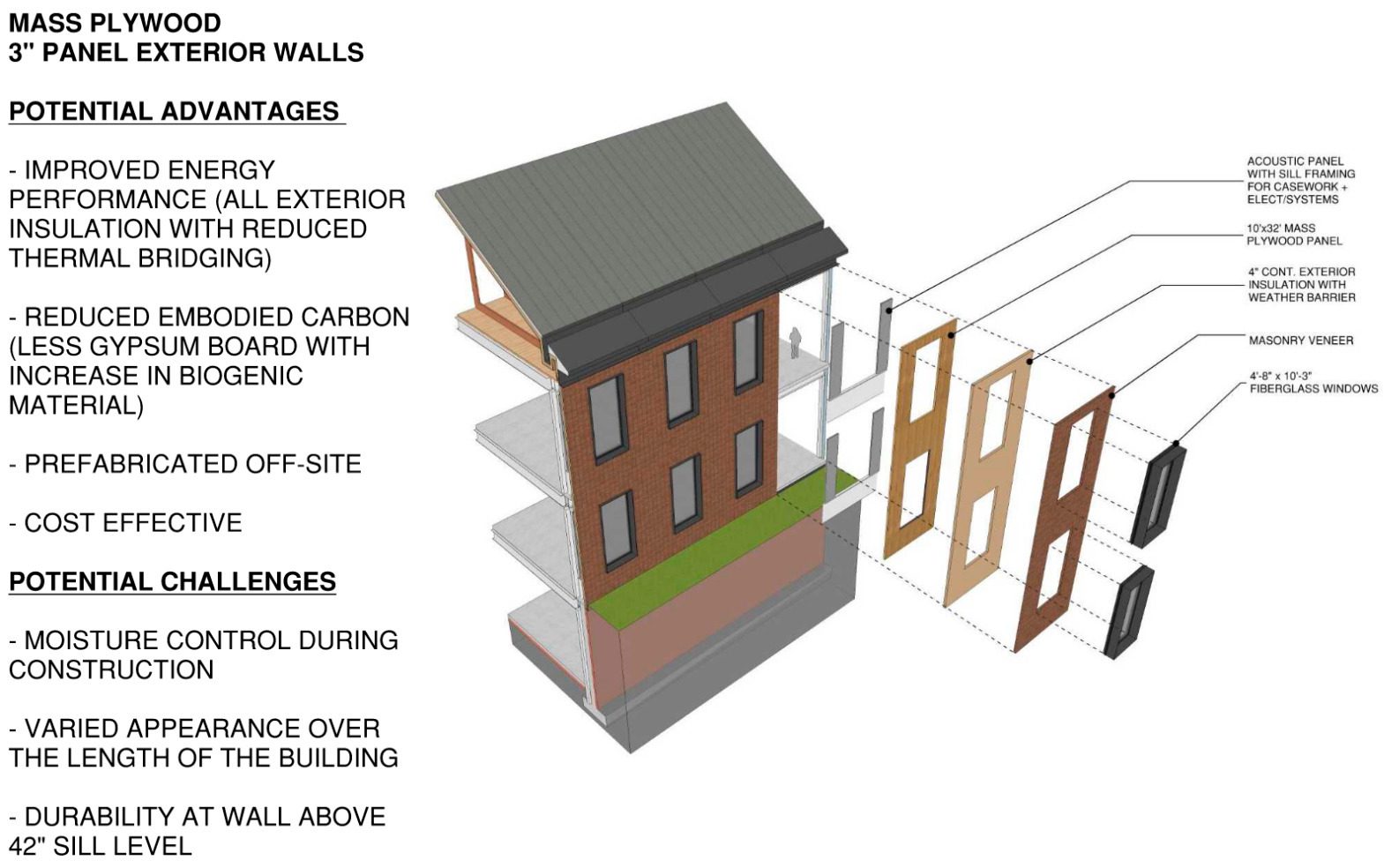

October 12, 2023Working with Andersen and Harver to innovate on the build process, we wondered if we could employ Mass Plywood Panels (MPP) for the envelope – which is one additional step in a prefabricated solution. Mass Plywood Wall and Roof panels are up to 10’ wide x 30’ long and up to 7” thick and can be fabricated from smaller trees and wood waste products. MPP walls come with a series of fabrication and carbon benefits. Framing the building’s walls and roof with MPP instead of the typical metal framed walls and roofs substitutes wood for a series of high-carbon content materials including metal framing, steel decking, drywall, and concrete. There are several more benefits to using mass plywood for the wall panels and attic floor with a sloped roof deck:

- Leaving wood finishes exposed incorporates natural warmth to the interior and reduces the need for additional finish material and labor

- Locally harvested and manufactured mass timber reduces shipping costs, impacts from emissions and activates local industries

- Energy savings yielding lower emissions

- Reduced peak loads on HVAC systems and 3% improvement on annual energy savings which equates to saving over $15,000 every year in the future

- MPP naturally reduces thermal bridges from the brick veneer ties

- The Building envelope’s R-Value would improve from R-16 to R-22

- Cost neutral compared to alternative cold formed framing

As far as we know, this is one of the first applications of MPP for the building envelope. As such, the team had the opportunity to learn a lot together.

In the Pacific Northwest, rain can never be ruled out during any season. The team had to weigh tenting the entire structure or allowing the MPP to get wet and follow up with sanding and staining after installation. The budget did not support tenting, and the team was relieved that water stains were not much of a problem. Sanding and staining MPP works well and is a cost-effective way to address water stains and other blemishes once the building is dried in.

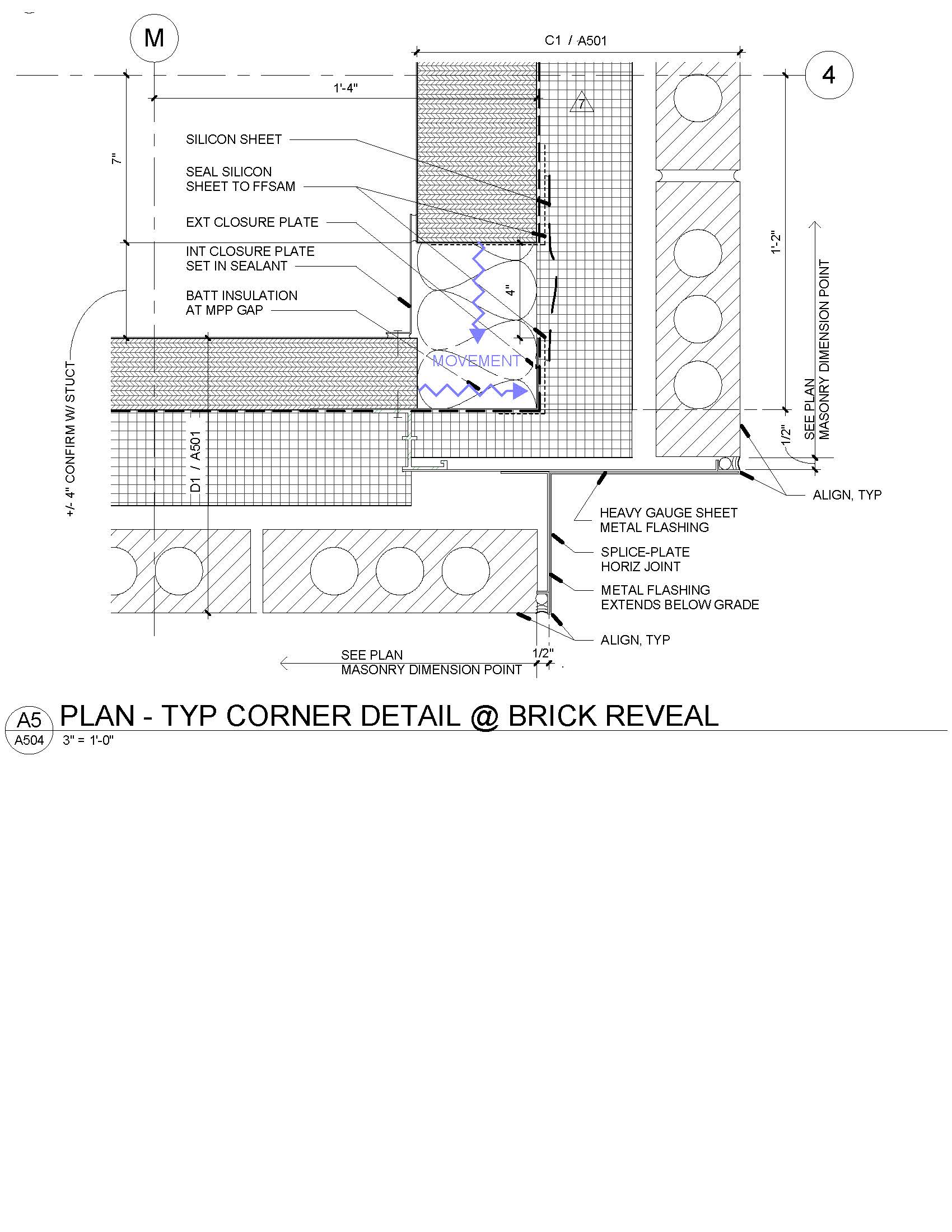

Given the sloping site, our team determined that shop applied Weather Resistant Barrier (WRB) made the most sense. However, due to the risk of damaging the shop-applied membrane during shipping and erection, it may make more sense to install WRB in the field in future applications when walls are easily accessible.

Mass plywood used for attic floor panels should have a temporary sheet added in the factory to help with adhesion. This would require only the seams to be field applied. Since the panels need to be dry for field application, some protection is better than none.

Some ideas we are exploring to address roof conditions in the future are: evaluating material fabrication and delivery times, designing the flat roof to slope to one edge to shed water while waiting for dry-in, terminating the exterior MPP no higher than the top of the attic floor to allow water to flow to the side of the building and not directly into the spaces below, and not cutting penetrations in the factory but rather cutting in the field when needed.

The envelope erection timeline was a big win for this project, and The Harver Company would gladly use MPP again. The original schedule estimated installing eight panels per day, which would require twenty workdays to install 156 panels. The Haver Company installed the entire MPP envelope in a little over four days. Saving this labor time provided a positive impact on the schedule and budget. However, the team was unable to leverage the fast erection into the critical path. For the next project, we will collaborate with the builder and develop roofing solutions that allow the fast MPP erection time be leveraged into the building’s critical path to shorten the overall dry-in timeline.

This project is a great win for WSU Vancouver and their students. Making the bold decision to use MPP alleviated the need for high-carbon content materials and saved energy and cost, and the result will be an amazing and innovative resource the entire Vancouver community can be proud of.